Copper Core Solder Spheres with Nickel Barrier Plating and Pure Tin Flash Plating - Product has been discontinued

Some limited inventory may remain in stock. Click Here to request stock check

Some limited inventory may remain in stock. Click Here to request stock check

EasySpheres CUEZPL-XX solder spheres are sold in MOQ of 10,000 spheres and we can also accommodate high order quantities. Stock sizes ranges from 0.012" to 0.020" with stable 6 Sigma manufacturing standards for tight dimensional quality control.

| Features | Benefits |

| High Core melt Temp of 1080C | Precision Standoff Height |

| High Density Capable | Easy Substrate cleaning and encapsulation |

| Excellent Electrical Conductivity | 5 to 10 times that of Tin Lead Alloys |

| Superior Thermal Conductivity | Approx 1.3 times that of eutectic alloys |

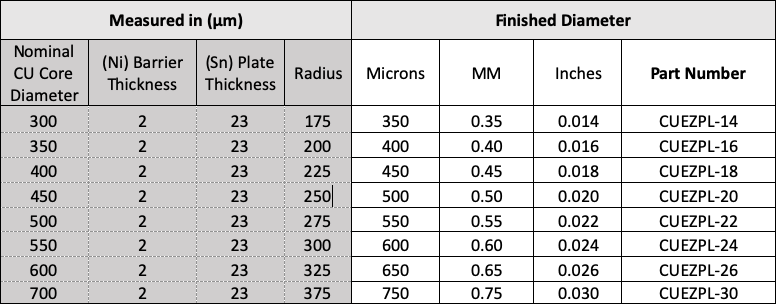

Dimensional Tolerances for Plated Copper Core Spheres

| Core Dia. | Core Tolerance | Barrier Thickness (Ni) | Plating Thickness (Sn) |

| 300-490 µm | ± 15 µm | 2 µm | 23 µm |

| 500-600 µm | ± 25 µm | 2 µm | 23 µm |

Plating Thickness Specifications

* Nominal CU Core Diameter indicates approximate standoff height

EasySpheres warrants this product to be defect free, with alloy purity in compliance of IPC-JSTD-006 guidelines.

There are no products listed under this category.